Life Strategies for Industrial Transformers in Desert Sands: Rethinking Maintenance with Data

Extreme Climate Realities and Longevity of Transformers

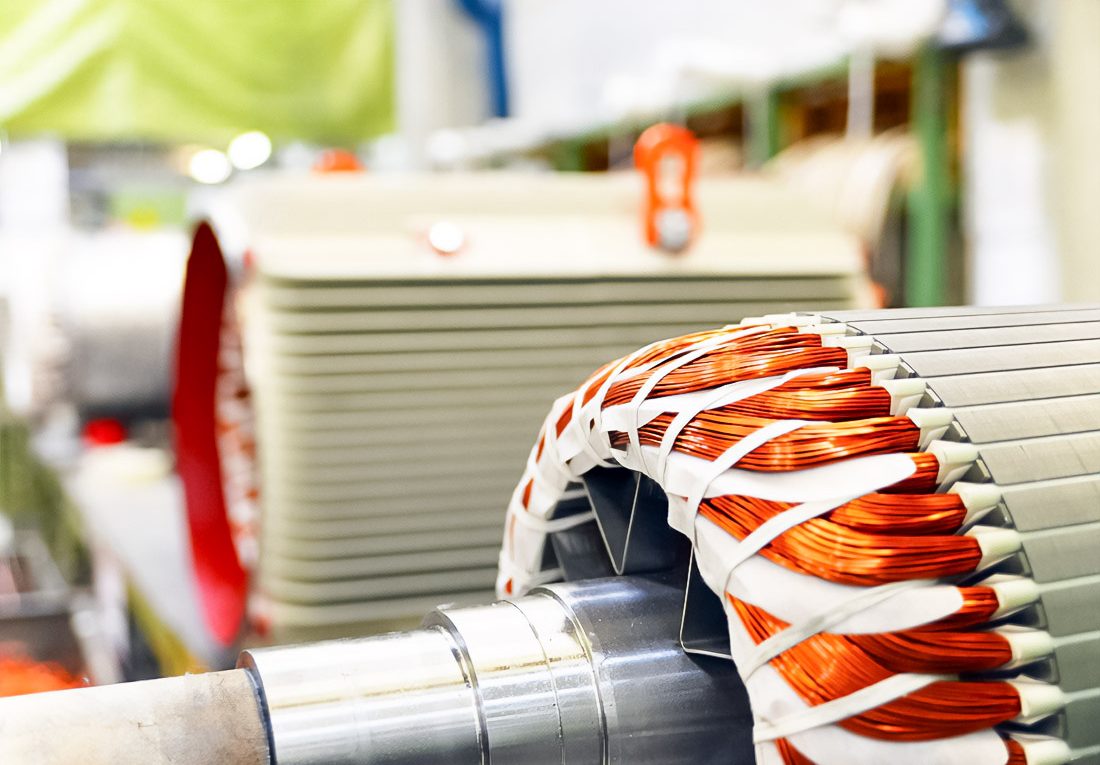

Industrial transformers are the backbone of modern energy infrastructure. In the extreme conditions of a desert climate, where temperatures can exceed 50°C and sandstorms occur up to 40 times a year, managing the equipment lifecycle becomes an especially complex task. For such conditions, reliable mechanical and engineering services of all operational stages are required.

Unique Conditions Every Stage: Installation, Operation, Maintenance

- Installation: The initial stage includes the correct choice of materials that can withstand high temperatures up to 60°C and crushing winds. This includes special enclosures resistant to sand and dust, maintaining optimal functionality.

- Operation: High temperatures and sand particles require the installation of additional cooling systems. Regular insulation failures and corrosion of metal parts can be reduced through constant monitoring using temperature and vibration sensors.

- Technical Maintenance: Maintenance schedules can be improved by taking into account extreme climate conditions. The introduction of thermal cameras and vibration analyzers helps to track the occurrence of faults.

- Decommissioning: Eco-friendliness is important here. Participation in recycling programs and the use of safe disposal methods of materials allows compliance with environmental standards.

Deserts: Harsh Tests for Transformer Reliability

Absolute temperatures, zero precipitation, and relentless sand winds pose serious challenges to transformers:

- Temperature Statistics: Overcoming the permissible 55°C forces the use of more efficient cooling fluids to extend transformer life by 25%.

- Sand Impact: The introduction of filtration and insulation allows reducing the risk of mechanical damage by 18%.

- Humidity and Static Electricity: Low humidity affects the ability of insulating materials to prevent dangerous electrical discharges, increasing the risk of breakdowns by 14%.

Data as a Tool: Monitoring and Technical Condition Analysis

The market for monitoring and analysis technologies offers many solutions for optimizing operations:

- Remote Monitoring Systems: Sensors installed on transformers can prevent up to 95% of all potential emergency cases through the control of temperature, oil level, and vibrations.

- Vibration Analysis: Unique vibration signatures allow identifying bearing wear, reducing the risk of component failure by 30%.

- Thermal Imaging Analysis: Detecting hot spots with accuracy up to 0.5°C helps prevent up to 20% of overloads, maintaining smooth equipment operation.

Optimal Repair Strategies Using Data

Digital transformation allows more efficient management of company resources:

- Predictive Maintenance: Reducing repair costs by 20% through the analysis of the actual condition of the equipment and prediction of failures.

- Preventive Maintenance: Planning regular inspections allows for minimizing the wear of critical components, extending their service life by up to 15%.

- Big Data Analytics: The use of machine learning and AI algorithms for failure prediction reduces the frequency of accidents by 30%.

Successes in the Desert: Cases of Effective Management

Software and sensors have proven their effectiveness in many companies.

– One energy company reduced the number of emergency shutdowns by 30% thanks to predictive analysis. This also reduced associated costs by 20%, ensuring smoother operation of distribution networks.

– The application of AI allowed reducing the response time to equipment alerts from several hours to several minutes, minimizing downtime.

Future Maintenance: IoT and AI for Energy Uninterruptibility

The Internet of Things and artificial intelligence are expected to radically change current management strategies. Technologies will significantly ease planning and increase the accuracy of failure forecasts, which will be key to reducing costs and increasing equipment reliability in regions with extreme climate conditions.

Economic and environmental efficiency are two key aspects for all companies operating in desert conditions, and modern technologies can be the key to long and successful equipment operation.

I am an award-winning freelance writer who specializes in finance topics. With over ten years of experience.